Fleet Managers Can Now Live-Manage Electric and Internal Combustion Engine Powered Vehicles Side-by-Side

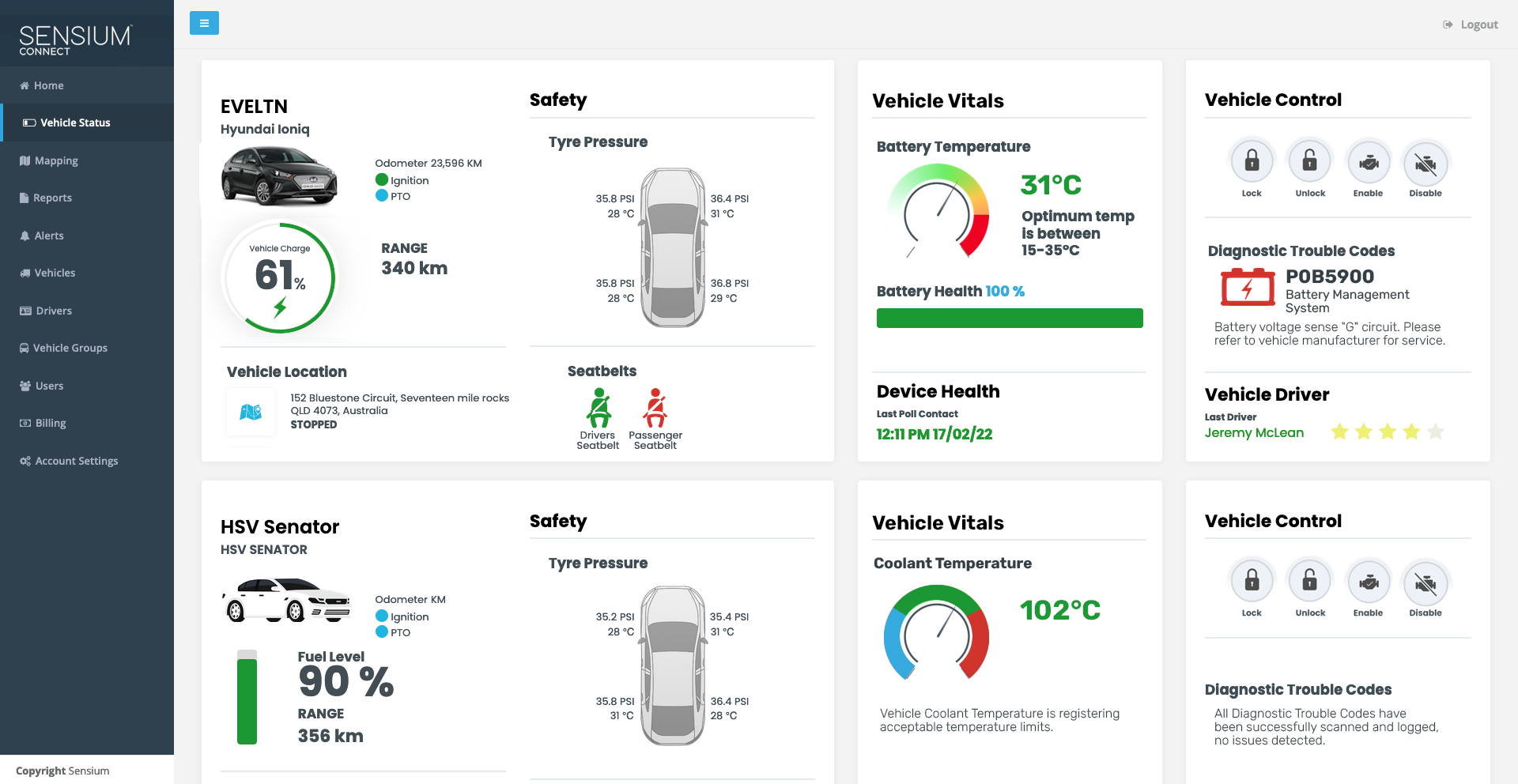

Sensium Fleet Telematics offers a groundbreaking platform that lets Fleet Managers monitor and control electric and ICE powered vehicles from a single dashboard.

The Australian based Sensium Fleet Telematics, developer and manufacturer of locally made vehicle telematics hardware and software has released an update to their Sensium Connect™ Fleet Vehicle Telematics dashboard, enabling organisations to live-manage electric fleet vehicles alongside traditional internal combustion engine powered cars.

SYDNEY, MAY 03, 2022

Headquartered in Brisbane, Queensland, Sensium Fleet Telematics are developers and manufacturers of their own proprietary Australian made fleet telematics hardware and software. Their flagship vehicle telematics hardware, the TB2-20 helps businesses increase productivity, improve driver safety and gain competitive advantage. Sensium securely logs over 200 million vehicle events across Australasia each month.

Announced at the 2022 Australasian Fleet Conference & Exhibition in Sydney, Sensium’s vehicle telematics hardware, the locally designed and manufactured TB2-20, has achieved a groundbreaking industry first integration with Electric Vehicles, after developing a way to decode and feed proprietary vehicle manufacturer data to the cloud. The Sensium Connect™ dashboard then enables organisations to live-manage EV fleet vehicles alongside traditional petrol powered vehicles. The Sensium Connect Vehicle Status dashboard displays information such as:

Odometer

Battery State of Charge

Battery Temperature

Battery State of Health

Driver & Passenger Seatbelts

Tyre Pressures

Tyre Temperatures

DTCs (Diagnostic Trouble Codes)

12v battery Condition

EV Charging State

BACKGROUND

2022 is proving to be a watershed year for Sensium, and in many respects the beginning of a new age for the company. Over the past 17 years, Sensium has built its reputation in the vehicle telematics industry off the back of local hardware and software development, and a commitment to the direct needs of fleet management and drivers.

However, when it comes to the early days of integrating electric cars into business or government fleets, ten years of discussions were largely driven by uncertainty.

The fear of the unknown generally stifles innovation, and in the case of electric vehicles being deployed in fleets, such concerns as range anxiety, poor battery life management, and the inability to fully integrate electric vehicles into fleet management systems, made any roll-out little more than a sustainability box to be ticked.

For Sensium, a strategy shift in 2018 was a turning point for the company. This shift demonstrated a dedication to some of the most sophisticated levels of CAN bus knowledge among fleet telematics firms in Australasia, if not the world. For the uninitiated, the CAN bus system is the equivalent of your body's nervous system for vehicles, Electronic control units (ECU's) act as parts of the body, and the CAN bus allows easy and efficient communication between ECU's.

But for GPS tracking firms, the inability to efficiently access and understand the CAN bus, as well as how to fully exploit the data that flows through a vehicle's nervous system, was stymied by the complexity of establishing what is a necessarily strong link between fleet telematics hardware and software.

It was at this point, in 2018, when the team's then 13 years of vehicle telematics expertise started to shine, allowing them to make significant advances in surfacing and acting on valuable vehicle data. As Sensium develops and produces all of its vehicle telematics hardware and software in-house, this eliminates significant roadblocks to interpreting the CAN bus.

Sensium was initially asked by an existing enterprise customer in Australia to extract real actionable vehicle data from the 906 and 907 Mercedes via the CAN bus. Although these were not electric vehicles, the experience and subsequent learnings acquired through this connection, and the assistance from vehicle manufacturers was crucial in unlocking data that had previously been trapped in the CAN bus's intricacies.

As a result of their knowledge of the CAN bus, Sensium' high-level engineers recognised an unrivalled appreciation for the tremendous advantages that electric vehicles could provide to fleet managers of large commercial and government vehicle fleets.

Managers of commercial vehicles typically take for granted the data in their fleet management systems. These generally provide an overall fleet health assessment, track odometer readings, service history, vehicle movement via GPS, and sometimes even more sophisticated capabilities like driver identification.

These features, like the aforementioned GPS tracking and driver ID systems, are available as standard options by Sensium, albeit at the highest level of dependability due to locally manufactured hardware, software and support. However, EV's offered something different: insight into the vehicle's inner workings via CAN bus to truly maximise return on investment for what is a rather substantial capital spend.

However, for Sensium, it was more than simply a recognition of the possibilities to unlock the data-driven knowledge embedded in electric vehicles; it was also an opportunity to propel the firm into a new era of self-substantiation. Essentially the business now had the keys to unlocking the secret sauce that all fleet managers required, the ability to truly integrate electric vehicles into a traditional fuel powered commercial vehicle fleet, with equality of data driving decisions for both drivers and fleet managers.

Armed with this information, and at a crossroads when it came to facilities for both their New Zealand and Australian offices, in 2020 CEO Jeremy McLean decided that the best solution for growth was to establish two new offices, each with state-of-the-art vehicle bays and Development Centres.

These new facilities on both sides of the Tasman, which are a technologist's and engineer's fantasyland, would make Tony Stark proud. The Development Centres’ are fitted with EV charging stations, the latest in 3D printing technology for rapid prototyping, laser etching tools, Oculus Quest VR headsets for each employee to explore 3D designs in virtual reality, plus many of the necessary tools, equipment, and technology to construct a space-shuttle (if needed).

With all of the tools at their disposal and knowledge of CAN bus's operations in relation to electric cars, Sensium were now ready to tackle the particular challenges that plagued fleet managers when mixing EV's with gasoline-powered cars.

THE ISSUE

Sensium's discussions with fleet managers over the last 10 years uncovered several issues that were largely caused by human behaviour. A fantastic illustration of this is the simple reporting and management of EV batteries. If a pool car is booked to be used and has run out of petrol, petrol stations can be found on every corner. When it comes to electric vehicles, if a battery is low, it could be hours until the vehicle is ready.

Even if a journey is brief, range anxiety influences employee behaviour in acceptance of electric vehicles in a fleet. Government and large fleet owners found they were purchasing EVs to “tick the green box”. But due to a lack of understanding of battery powered vehicles, these new vehicles were left alone in the lower levels of their underground car parks, while the petrol vehicles continued to be used.

THE SOLUTION

However, in what is a game-changer, since Sensium creates end-to-end hardware, software and services utilising their TB2-20 when installed in EV's like Tesla's, Hyundai EV's and others, Sensium developed a way to feed live battery status data, trouble-codes and more to the Sensium Connect™ dashboard.

From the Nissan Leaf's debut in 2011 to the present growing electric vehicle industry in 2022, these breakthroughs by Sensium address a decade of fleet management challenges.

Not only this, but Sensium Connect™ allows securely encrypted remote vehicle control for electric vehicles as well. Remote vehicle shutdown, door lock and unlock are all now possible with ease.

However, it's not just drivers that are taken care of when live-reporting tyre pressure information, tyre temperatures, seat-belt status, battery temperature and driver identification - the capitalised value of an electric vehicle at the conclusion of a lease term can also be maximised.

The condition of the battery is the most significant factor in determining an electric vehicle's value at the conclusion of a lease. Consumers who buy second-hand are specifically concerned with battery health, therefore peak battery condition is crucial.

Before the electric vehicle is put up for sale, a thorough report can be created using Sensium Connect™, maximising the sales price by including many details of the automobile's condition.To pull all of this together, our proprietary CAN Monitoring software runs on our locally developed and manufactured TB2-20 Vehicle Telemetry Device. This continually monitors and interrogates the CAN bus for certain data being sent around the vehicle, such as:

Odometer

Battery State of Charge

Battery Temperature

Battery State of Health

Driver & Passenger Seatbelts

Tyre Pressures

Tyre Temperatures

DTCs (Diagnostic Trouble Codes)

12v battery Condition

Outside Air Temp

EV Charging State

And many other pieces of data applicable to fleet management and driver safety

These are not simple Service Mode 1 messages, and require decoding per vehicle make/model/year. The data is packaged by the TB2-20 and sent to the platform, which then decodes the message, and understands the contents. This is securely passed to the cloud platform, stored (for a minimum of 7 years), and displayed in an easy to understand User Interface (UI).

This data, in a decoded form, is also made available to 3rd party software in their API. This helps Pool Vehicle Booking Software to automatically select the best vehicle for a driver's needs.

The Vehicle Status dashboard from Sensium, as an add-on to Sensium Connect™, is now available in beta to early access customers and EV industry advocates, and is already being utilised to make educated decisions about electric vehicle use.

However the real magic of Sensium's approach to committing 18 years of local resources to end-to-end vehicle telematics hardware design, local manufacture, software and services is soon to be widely demonstrated, with the imminent roll-out of the service being immediately available to all customers with suitable Electric Vehicles.

Since its inception, co-founder and CEO Jeremy McLean has taken a human-centred approach to all aspects of development and release. Sensium's sophisticated electric vehicle fleet management solutions are the product of this attitude, and what we are seeing now is only the beginning of a journey which started 18 years ago.

TECHNICAL SPECIFICATIONS

SAFETY AND ELECTRICAL APPROVALS

The Regulatory Compliance Mark (RCM) indicates that the products are compliant with the Australia and New Zealand radio-communications and Electromagnetic Compatibility (EMC) standards. These are the standards needed to ensure the safety of products and that they are fit for their intended use, protect the radio spectrum, minimise interference and allow effective use of radiocommunications services.

TB2-20 SPECIFICATIONS:

Network - 4G CAT M1

Size - 92 x 55 x 25mm

Weight - 114g

Backup Battery - 3.7V 1250mAh

Operating Voltage - 6 ~ 42V DC

Learn more about Sensium and Sensium by visiting www.sensiumlabs.com and www.sensium.com.au.

Address

3/152 Bluestone Circuit, Seventeen Mile Rocks, QLD, 4073 Australia

Postal Address

PO Box 3323, Darra

QLD, 4076, Australia

1800 FLEETGPS (1800 353 384)

sales@sensium.com.au